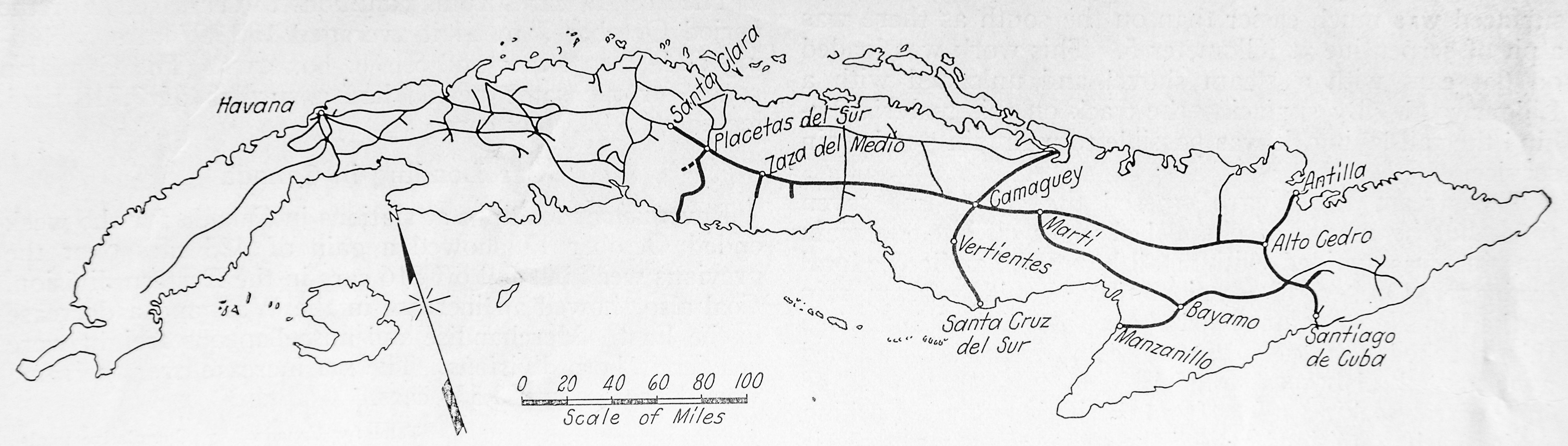

In order to develop a new sugar cane territory the construction of the Santa Cruz branch was planned by the railroad company and subsidized by the Cuban government. This branch connects with the main line at Camaguey and runs south 98.5 kilometers (61.2 miles) to Santa Cruz del Sur on the south coast of Cuba.

The first 33 kilometers from the main line south to Vertientes had been built in part when instructions were received to complete the building of this branch. At Vertientes there is a large sugar central or mill, so the building of the first 33 kilometers was assured but whether to build from Vertientes to Santa Cruz or not was a question—it is 65.5 kilometers from Vertientes to Santa Cruz. However it was decided that the development of this virgin tropical jungle into a sugar cane producing area would warrant the expense. On March 16, 1924, authority was received to commence the work on the extension and on April 1 forces had been organized and work begun. The expiration date of the subsidy was December 14 and it was necessary to make every move count as the line had to be accepted and in operation by that date.

Rainy Season the Greatest Obstacle

The greatest problems to overcome were the rainy season the shortage of labor, the high prices paid labor during “the dance of the millions,” which was still being felt, and the fact that all track material had to be purchased in the United States and shipped to the island. The rainy season starts about the middle of May and lasts until into December, and this slows up work more than any other single factor. One has to experience a rainy season in the tropics to fully appreciate the old negroes remark “When it do rain it sure do rain.”

The shortage of labor was relieved by the immigration to Cuba of large numbers of Spaniards, Germans, Poles, Russians, Jamaican negroes and a few French. ‘The different nationalities were as far as possible placed in separate gangs but on one particular occasion two Frenchmen were working with a German gang. It did not take long for this mixture to come to a boil as one night a fight started in the dining car, and though the Frenchmen were outnumbered forty to one, they were able to make a good accounting for themselves by the use of hot soup and heavy table-ware. The dining car after the fight resembled an old time outfit car in the spring.

To overcome the lack of communication, a telephone line was constructed as fast as the clearing was out of the way and the telephones necessary to handle the work installed. This enabled better handling of material and supplies than could possibly have been secured by depending on the old time messengers. As soon as this line was constructed the kilometer post markers were put up. This enabled the engineers to have an easy check on the deliveries and the contractor’s work and was an aid in making reports.

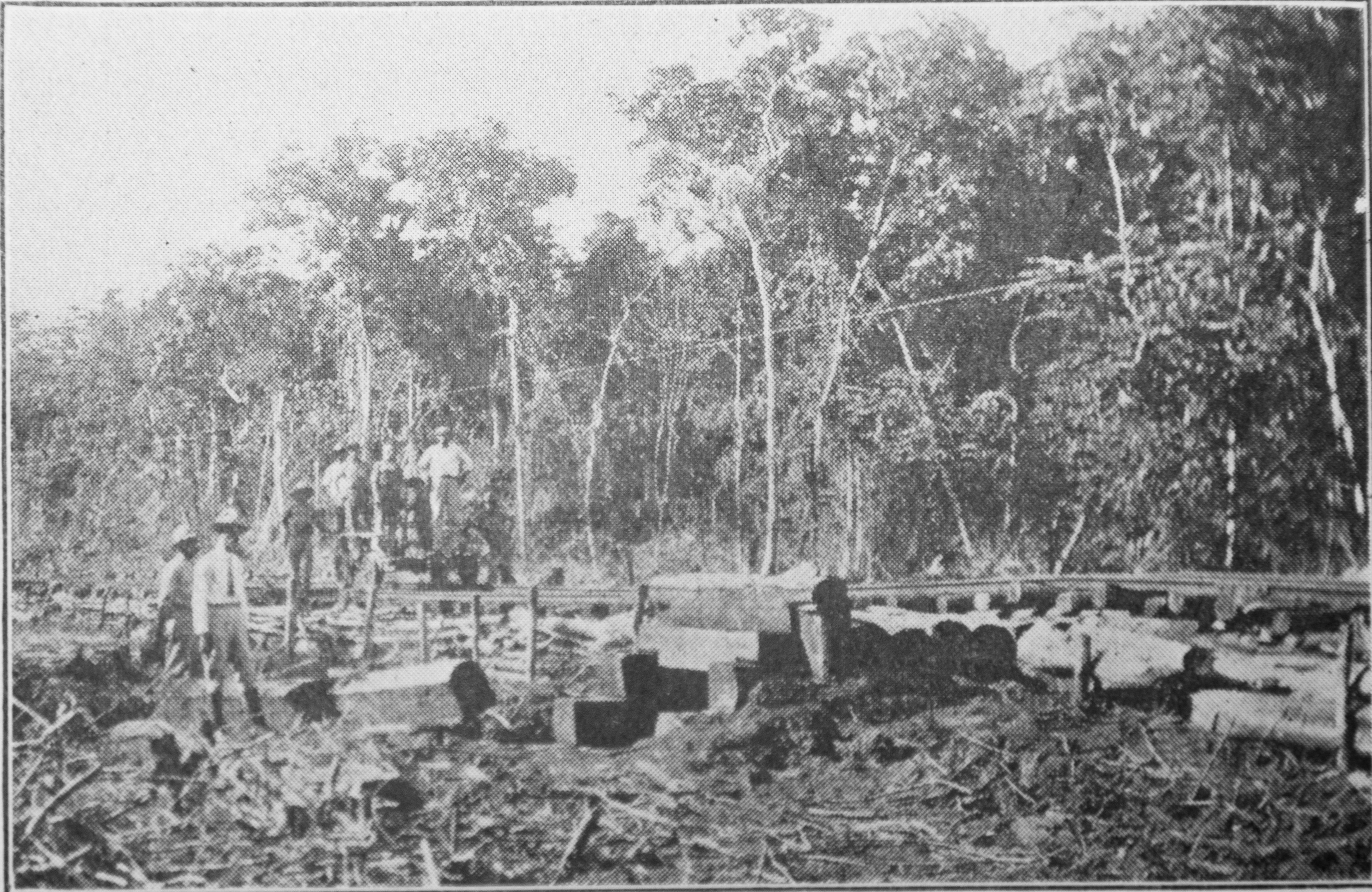

Clearing Work in the Tropical Jungle

The clearing was done by contract. To watch a clearing gang at work would interest an American as everything but the big trees are cut with machetes. The large trees are cut with a saw. A good macheteman is an artist in his work. The machete is handled different from the axe; instead of a full arm swing the force of the machete blow is given by the wrist. A gang of machetemen will attack a tropical jungle so dense with undergrowth of vines and brush that one cannot pass through it, but all this soon falls before them.

It was decided to do only the grading at stream crossings and in cuts ahead of the track laying. The soil along the location of the line consists of decayed vegetable matter and the construction of other lines under similar conditions had proved that this material made expensive maintenance. As a fair grade of sand shale was to be had in a pit at Kilometer 65, this material was used for embankments.

All the culvert and trestles that could be framed were contracted, the contractor furnishing the material from the adjacent jungles, as teaming any distance was out of the question. The culverts, like the one shown in one of the pictures, were made of mahogany. All bridge work requiring the use of a pile driver was handled by company forces.

The building of the Santa Cruz wharf was gotten under way immediately upon advice to commence construction, as the time limit made it necessary to carry on the work from the south coast towards the north and from Vertientes south. The wharf was constructed by company forces, a track pile driver being used to do the driving. The driver was loaded on the lighter at Manzanillo and towed to Santa Cruz. Upon reaching there the end of the lighter with the driver was pushed toward the shore until striking bottom and the first bent of the wharf driven, after which the lighter was backed out far enough to drive the second and third bents, then the driver was landed on these bents and worked its way to shore. In order to extend the wharf so as to secure deep enough water to permit the operation of loaded lighters and a tug the driver had to be turned. It was again loaded on the lighter, the lighter turned and the driver backed onto the wharf. Then with the driver headed toward the sea the wharf was extended to a length of about 880 ft.

Native Woods Make Hard Ties

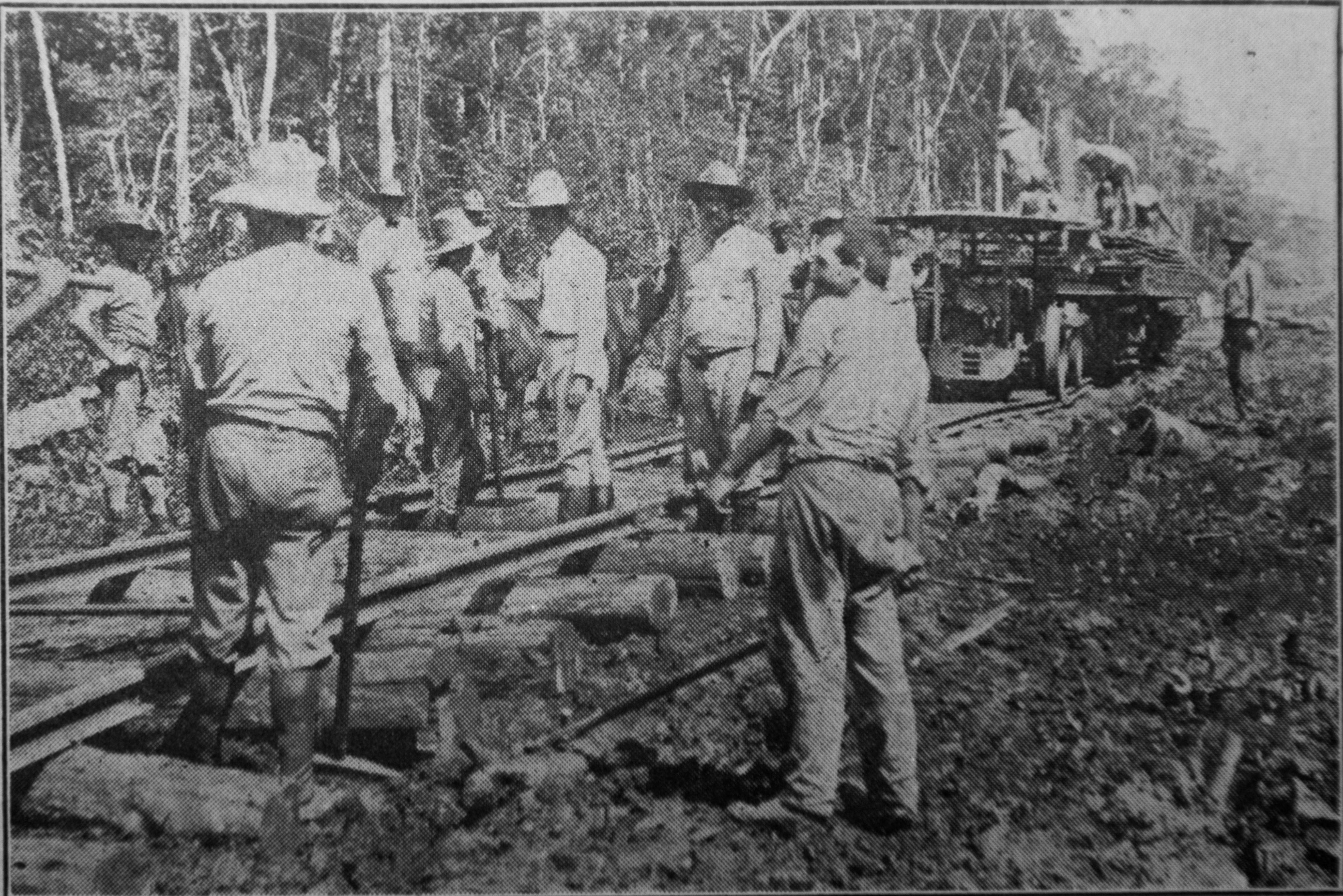

Ties were contracted for locally to be delivered in quantities of 2,100 to the kilometer but clue to the rains delaying the contractor it was necessary to assist with ties from the main line. It is interesting to know that the better grades of native ties are so hard it is impossible to drive a spike in them without first drilling a hole. Templets were made to mark the spike holes and drilled in advance of the rail-laying. On the north end all rail-laying was done by company forces but on the south end it was contracted. However. due to labor difficulties with the contractors’ forces it was necessary for the company to complete the work.

About every trick known on railroad construction was used and some never tried before. Due to the manner of construction without first preparing a completed roadbed, a Fordson track tractor was used instead of a locomotive at the front on the south end. This tractor would handle two standard flat cars loaded with rail and track fastenings. at the lagoon crossings and· in the low lands it was impossible to surface the track on the local soil, so the timber cleared from the right-of-way was trimmed and limbs from three to six in diameter were used to make a corduroy road ahead of the rail-laying. Instead of placing the logs transversely they were laid longitudinally and the cross ties laid and surfaced on them. The question has been asked as to whether this construction will not cause trouble later, but it is thought not as this material, was buried so deep in the original soil and such heavy raises of the sand shale were made that there appears little likelihood of these logs moving under traffic.

The construction from the north to the south did not offer any extraordinary difficulties in the matter of furnishing power, equipment, material and! supplies as a rail connection with the main line was always maintained, but the building from the south to the north was different. On this work everything had to be lightered from Manzanilla to Santa Cruz. After the pile driver came a locomotive, Fordson track tractor, flat cars, a caboose, outfit cars and coal. Two lighters were used, one of them being provided with three tracks, each holding three cars. One tug was used to handle either one of the lighters or both as was required. The locomotive was used to do the unloading at the wharf in the Santa Cruz material yard and to deliver material as far north as the track would permit. Beyond that point it was handled by the tractor.

Train and Engine Crew Was Resourceful

The train and engine crew that went from Manzanillo to Santa Cruz with the locomotive stayed on the job until the steel was connected and performed splendidly. They did nearly all of their own repair work, maintaining the locomotive in serviceable condition, on one occasion even making bearings out of hardwood, and this hardwood was still in service when the locomotive came through on its own wheels to the Camaguey shops. In general, coal was used for fuel but whenever there was a shortage, wood was substituted.

The pictures give some idea of the terrain that had to be crossed. As the rains continued, the ground became so soft horses would sink to their bellies at every step and, if care was not exercised by the rider, would bog. In fact bulls also mired, often making it necessary to snake them out.

On the north end, the problem of keeping the track surfaced was much easier than on the south as there was a pit of serpentine at Kilometer 5. This work was loaded on flat cars with a steam shovel and unloaded with a Lidgerwood. By surfacing the track on this material behind the rail-laying, it was possible to maintain good train service.

The stream Rio Negro crossed the center line seven times but by means of channel changes all but one main crossing was avoided, with small boxes to handle the local drainage. On several occasions there would be heavy rain in the Rio Negro water shed above the railroad and when this reached the right-of-way everything was washed away and the laborers would be seen on tree stumps and in the trees seeking safety from the high water. Working under such conditions caused the men to contract malaria and “fiebre” until the drainage and sanitary work provided a more healthful condition.

The rails were connected at 5:25 p. m. on November 19, at Kilometer 68.18. As soon as the steel was laid to Kilometer 65 a second shovel was cut into the pit at that point and this outfit, together with the one working at Kilometer 5, supplied material for making a running surface for the remaining distance into Santa Cruz.

On December 12 the inspector general of the railroad commission made a trip over the new line and accepted it. On the fourteenth scheduled trains were run and the company secured the subsidy. It was said frequently during the course of the work that the line could not be completed on time, but due to the splendid results accomplished by men employed it was done. The natives living near the right-of-way were interested in the construction work and spoke of the railroad as “Linea Electricidad” or in English, “a line built like lightning.”

###